Quality characteristics

| Treatment | Elution of chromium | Corrosion resistance | Scratch resistance | Contact resistance (grounded) | Fingerprint resistance | Alkali resistance | Solvent resistance |

|---|---|---|---|---|---|---|---|

| ZG treatment | No elution | SST240h, white rust occurrence 10% or less |  |

∞ | ΔL≤0.5 |  |

|

| ZC treatment | No elution | SST72h, white rust occurrence 10% or less |  |

10-5〜10-4Ω | ΔL≤1.0 |  |

|

Elution of chromium: Amount of chromium elution measured after the specimen has been immersed for 3 minutes in boiling water

Corrosion resistance: Salt spray test (JIS Z2371)

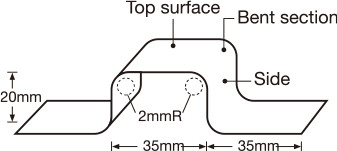

Scratch resistance: Appearance of the coating layer during processing

Contact resistance value: Measured by the four-terminal, four-probe method (Dia Instruments MCP-TPO3P)

Corrosion resistance: Salt spray test (JIS Z2371)

Scratch resistance: Appearance of the coating layer during processing

Contact resistance value: Measured by the four-terminal, four-probe method (Dia Instruments MCP-TPO3P)

Fingerprint resistance: Difference in brightness (ΔL) before and after impression with artificial finger-smudge solution (JIS K2246)

Alkali resistance: Appearance after immersion for 2 minutes in alkali degreasing agent (Nippon Paint SD-270) adjusted to pH of 12 and a temperature of 40°C

Solvent resistance: Appearance after immersion for 2 minutes in acetone

(Evaluation standard for alkali resistance and solvent resistance/ ○ : No change, △ : Some discoloration, × : Film peeling)

Alkali resistance: Appearance after immersion for 2 minutes in alkali degreasing agent (Nippon Paint SD-270) adjusted to pH of 12 and a temperature of 40°C

Solvent resistance: Appearance after immersion for 2 minutes in acetone

(Evaluation standard for alkali resistance and solvent resistance/ ○ : No change, △ : Some discoloration, × : Film peeling)