Quality characteristics

| Sample | Elution of chromium | Corrosion resistance (before painting) (8 hrs of SST) |

Paint adhesion | Corrosion resistance after painting (150 cycles of CCT) |

||

|---|---|---|---|---|---|---|

| Name | Treatment | Primary adhesion | Secondary adhesion | |||

| ZAM® | ZP treatment | No elution |  |

|

|

|

| Galvanized Steel | Chromate treatment | Elution |  |

|

|

|

| Electrolytic Zinc-coated steel | Chromate-free Phospahte treatment | No elution |  |

|

|

|

The above data is an example of our products.

Elution of chromium : Amount of chromium elution measured after the specimen has been immersed for 3 minutes in boiling water

Corrosion resistance : Salt spray test (JIS Z2371) 8 hrs ( ○ : White rust occurrence 10% or less, × : white rust occurrence more than 10%)

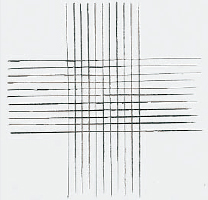

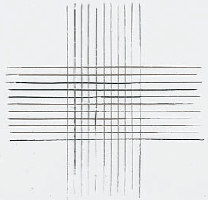

Paint adhesion : Primary adhesion : Lattice pattern (1 mm) cutting and cellophane tape peeling test ( ○ : no peeling, × : peeling)

Paint adhesion : Secondary adhesion : After immersion for 2 hours in hot water (90°C), lattice pattern cutting and cellophane tape peeling test ( ○ : no peeling, × : peeling)

Corrosion resistance after painting : Combined-cycle test (JIS G0594) 150 cycles (superior ◎ ○ △ inferior)

Corrosion resistance : Salt spray test (JIS Z2371) 8 hrs ( ○ : White rust occurrence 10% or less, × : white rust occurrence more than 10%)

Paint adhesion : Primary adhesion : Lattice pattern (1 mm) cutting and cellophane tape peeling test ( ○ : no peeling, × : peeling)

Paint adhesion : Secondary adhesion : After immersion for 2 hours in hot water (90°C), lattice pattern cutting and cellophane tape peeling test ( ○ : no peeling, × : peeling)

Corrosion resistance after painting : Combined-cycle test (JIS G0594) 150 cycles (superior ◎ ○ △ inferior)