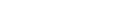

Dynamic friction coefficients of various types of coated steel

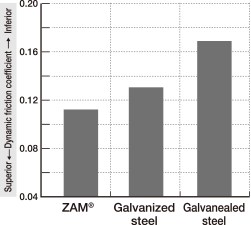

Sliding test conditions

| Sample size | 0.8 mm (thickness) x 30 mm(width) x 300 mm (length) |

| Press oil | Z5 (Idemitsu Kosan) |

| Pressing pressure | 0.72、1.45、2.90N/mm2 |

| Pressing force | 1、2、4kN |

| Pressing area | 46×30mm2 |

| Withdrawal rate | 1000mm/min |

| Mold surface roughness | #1000 (Polishing for each session) |

| Mold material | SKD11 |