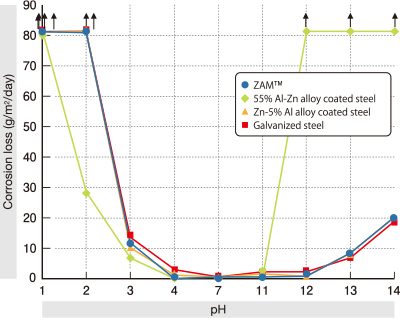

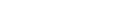

Acid / alkali resistance

- Test method

- ・Solution: Starting with an aqueous solution containing 1 g/L Na2SO4 as the base mix, its pH was varied from 1 to 14 by adding H2SO4 on the acidic side and NaOH on the alkaline side.

- ・To determine corrosion loss test pieces (n = 3) were immersed for 24 hours in a solution adjusted to each pH at 30°C, and the corrosion loss was determined. The cut edges and bottom surfaces of the test pieces were sealed.

In acidic and alkaline aqueous solutions, ZAM™ shows the same cor rosion behavior as other zinc-based coated steel sheets.

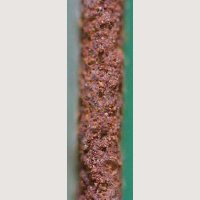

Corrosion weight losses of coated steel sheets

in acidic and alkaline aqueous solutions

(Thickness: 2.3 mm, coating weight: 80/80 g/m2, untreated)