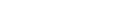

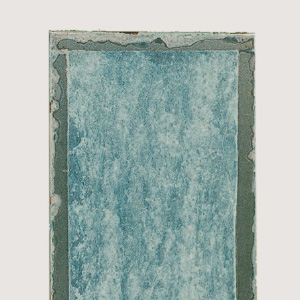

Appearances of flat parts after salt spray test

ZAM™ Thickness: 2.3 mm 90/90 g/m2 ZCS treatment

Post hot-dip galvanized product HDZT77 (HDZ55)

Thickness: 2.3 mm 560/560 g/m2

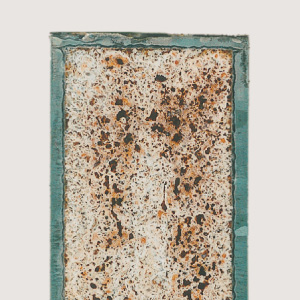

Appearances of cut edges after salt spray test

ZAM™ Thickness: 2.3 mm 90/90 g/m2

Post hot-dip galvanized product HDZT77 (HDZ55)

Thickness: 2.3 mm 560/560 g/m2