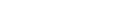

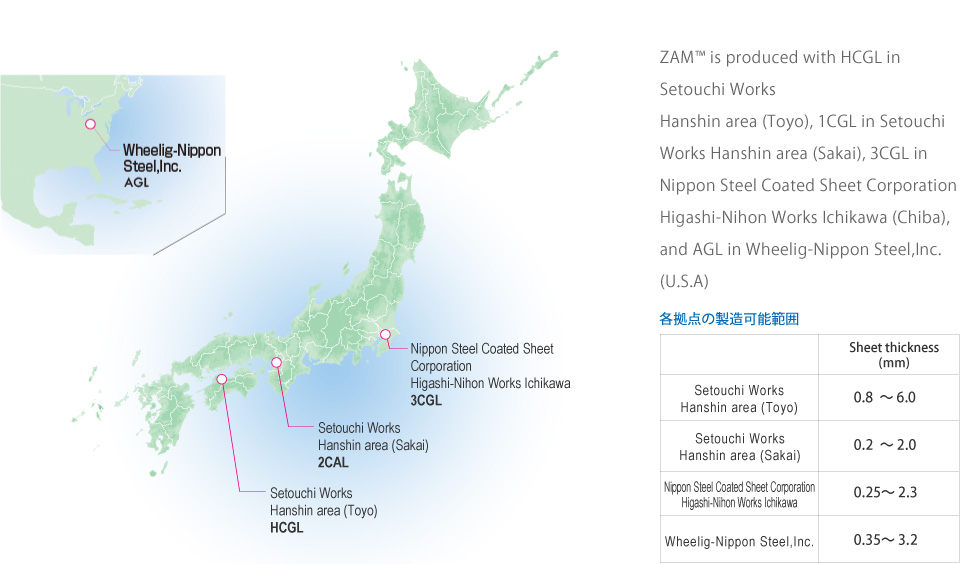

Production bases

Setouchi Works Hanshin area(Toyo) HCGL(hot dipping line)

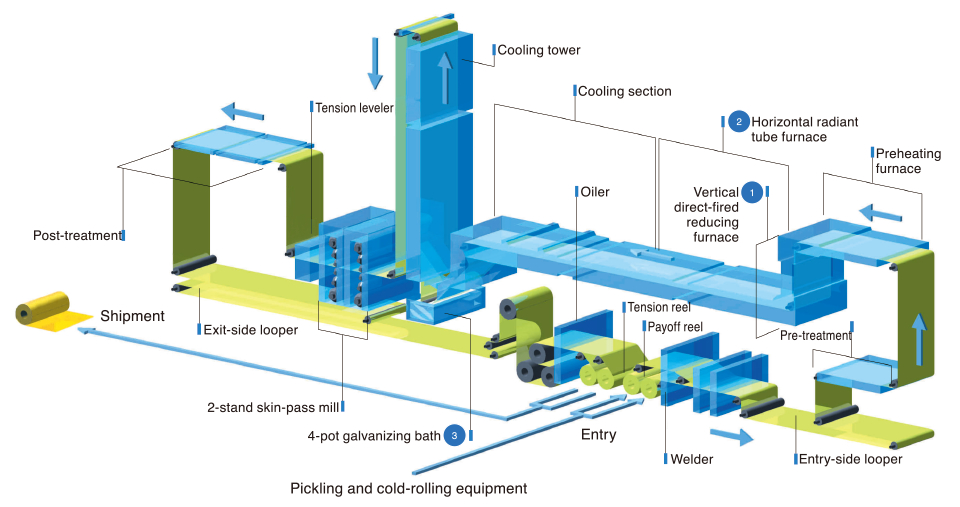

In this hot dipping line (HCGL), a vertical direct-fired reducing furnace and

a horizontal radiant tube furnace are combined to achieve improvement in both annealing furnace operation and product quality.

Incorporating four pots, this production line is capable of making several types of coated steel sheets (ZAM™, Hot-dip galvanized sheet).

In addition, it covers a wide range of steel sheet thicknesses.

HCGL annealing furnace

(Vertical direct-fired reducing furnace)

HCGL annealing furnace

(Horizontal radiant tube furnace)