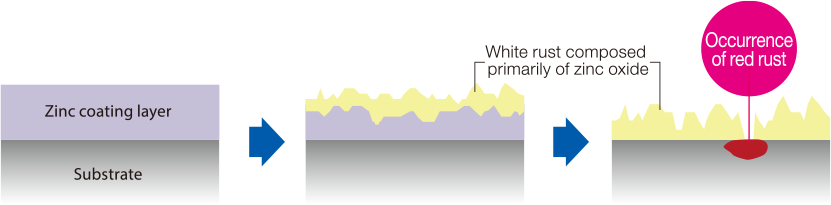

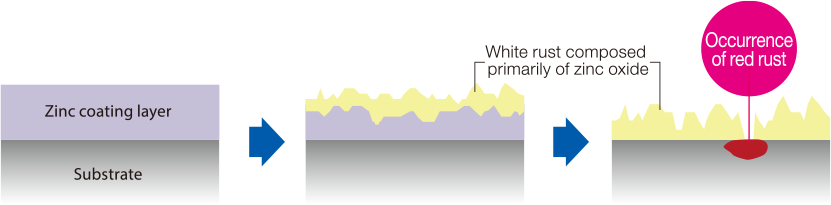

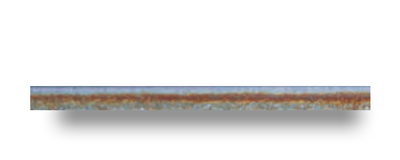

Hot-dip zinc-coated

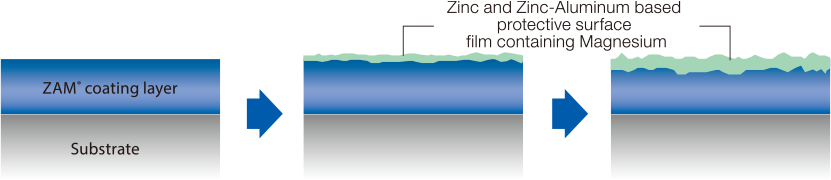

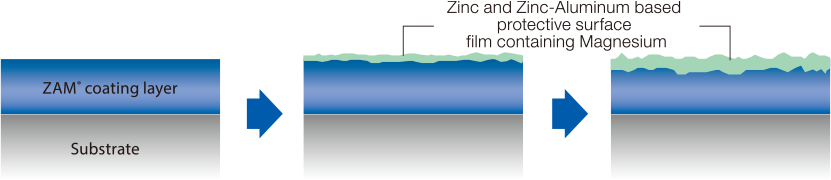

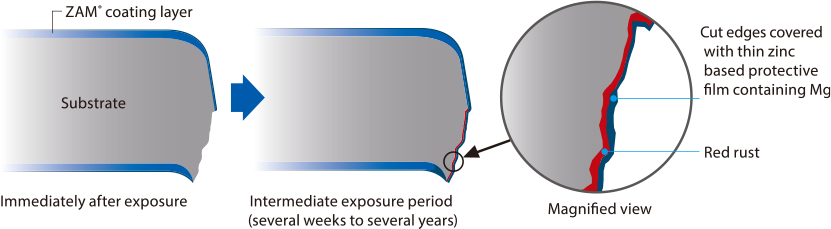

Excellent corrosion resistance is achieved on cut edge of ZAM™ with a fine zinc-based protective film that contains Mg leaching from the coating layer.

(Plate thickness; 3.2 mm)