1. Welding machine

ZAM™ can be welded with a off-the-shelf welding machine. Welding environment can be improved with the use of invertercontrolled welding machines developed by equipment manufacturers to reduce spatters.

2. Welding wire

Welding wires for carbon steel and structural steel can be used. However, to reduce spatters, blow holes, pits, and other defects, it is advisable to use welding wires developed specially for galvanized steel. Recommended wires

are shown on the right.

3. Shielding gas

The third-class carbon dioxide stipulated

in JIS K 1106 is used. (The combination of pulse current and Ar+20% CO2 gas will tend to decrease spatters to a greater extent.)

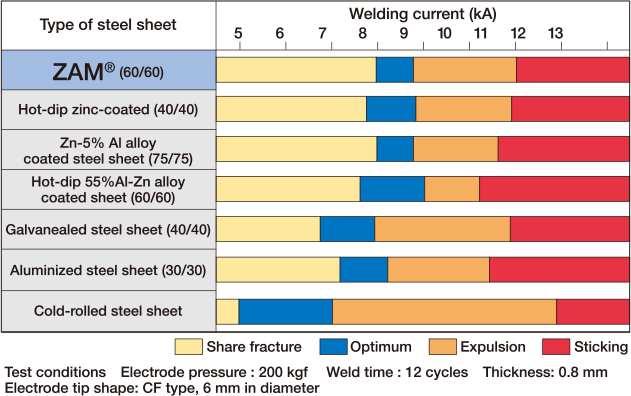

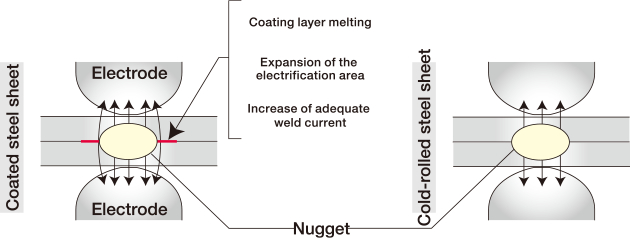

4. Welding current and voltage

When welding ZAM™ at the same speed as in the case of hot- or cold-rolled steel sheets, the initial welding temperature should be set slightly higher as more heat is absorbed by the evaporation of coating material (current to be raised by 5%-10%).

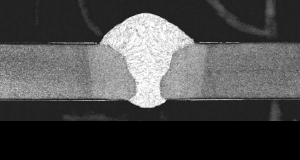

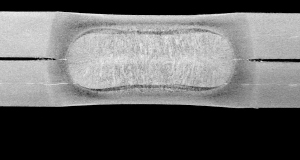

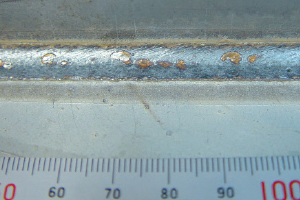

5. Welding speed

When such defects as blowholes or pits are found, the welding speed should be set lower than in the case of hot- or coldrolled steel sheets. Good beads can be made if weld speed is slow enough to release zinc vapor from the surface of the molten metal pool.

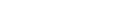

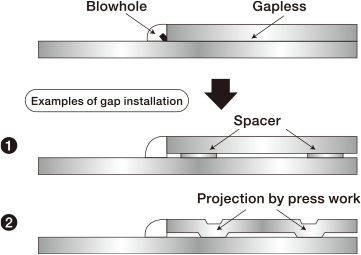

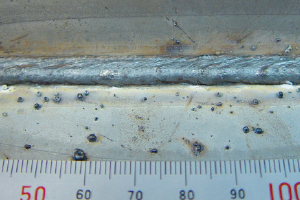

6. Installation of gaps

Lap fillet welding tends to cause such defects as blowholes or pits frequently. The most effective countermeasure is to set up gaps between steel sheets. A gap of 0.6 mm or wider helps substantially reduce these defects.

Recommended welding wires for class 400N substrates

|

Recommended welding wire brand (shielding gas: Carbon dioxide) |

| General-purpose wire |

Nippon Steel Welding & Engineering Co., Ltd.: YM28,

Daido Steel: DS1A, etc. (equivalent to YGW12) |

Wire

for coated steel sheets |

Nippon Steel Welding & Engineering Co., Ltd.: YM28Z (G49A0C0) |

| Flux-cored wire |

Nippon Steel Welding & Engineering Co., Ltd.: SM-1 (T49J0T15-0CA-G-UH5),

SM-1F (T49J0TI-0CA-UH5),

|

●Please consult us when welding wires for steel sheets other than class 400N are used.