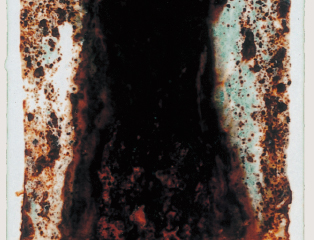

Appearances of arc weld zones after salt spray test

ZAM™ Thickness: 2.3 mm 90/90 g/m2

Weld beads

Weld beads

Zn-5% Al alloy coated steel Thickness: 2.3 mm 90/90 g/m2