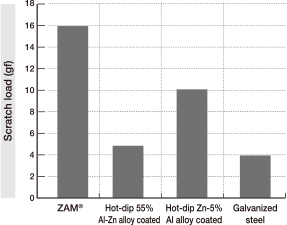

<Reference> Hardness of the coating layer (Vickers hardness (HV) measurement examples)

| ZAM™ | 140〜160 |

| 55% Al-Zn alloy coated | 100〜110 |

| Zn-5% Al alloy coated | 80〜100 |

| Galvanized steel | 55〜65 |

| ZAM™ | 140〜160 |

| 55% Al-Zn alloy coated | 100〜110 |

| Zn-5% Al alloy coated | 80〜100 |

| Galvanized steel | 55〜65 |

| Testing needle material | Sapphire |

| Testing needle tip radius | 0.05mm |

| Load | 0.0196〜0.196N(2〜20gf) |

| Travel distance | 20mm |