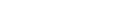

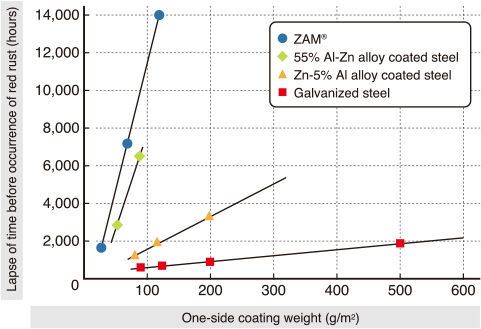

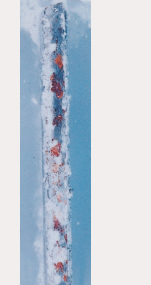

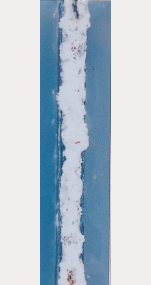

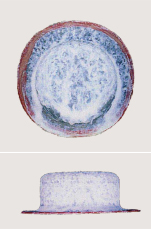

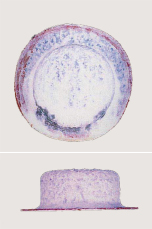

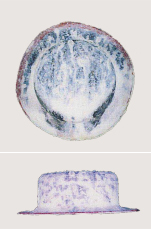

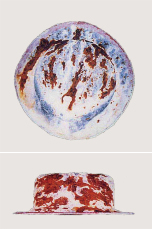

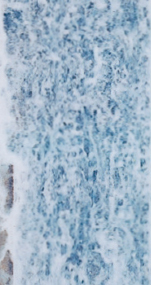

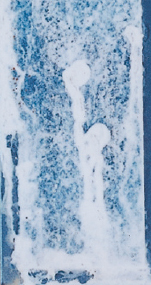

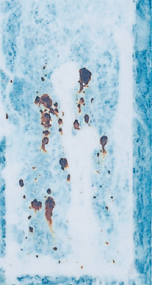

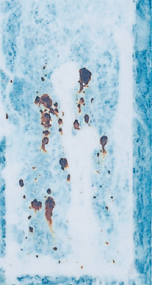

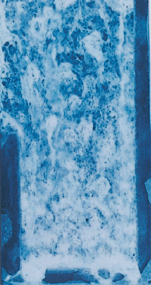

Results of salt spray test (SST: JIS Z 2371) Appearances of specimens after salt spray test

(Coating weight: 90/90 g/m2, untreated)

ZAM™

55% Al-Zn alloy coated steel

Red rust

occurred.

occurred.

Zn-5% Al alloy coated steel

Red rust

occurred.

occurred.

Galvanized steel