Electrical conductivity

equivalent to that for

chromate treatment

+ Weldability

A list of chromium-free treatments for ZAM™

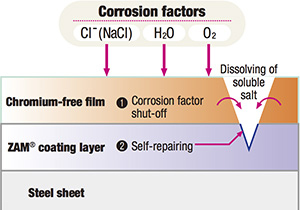

Anticorrosion mechanism of films

Mechanism of corrosion control by chromium-free film

(1)Corrosion control with environmental deprivation

The chromium-free film covers the coating layer uniformly

to prevent direct contact with corrosion factors.

to prevent direct contact with corrosion factors.

(2)Corrosion control by self-repairing function

If the chromium-free film is damaged due to processing

for instance, soluble salt dissolves under a moist environment to

form insoluble salt at the damaged are for self-repairing.

for instance, soluble salt dissolves under a moist environment to

form insoluble salt at the damaged are for self-repairing.